Types of heat exchanger

Typically, heat exchangers are used to allow heat from liquids or gases to pass to other liquids or gases, without the two coming into direct contact. They work according to the second law of thermodynamics, that is that heat will automatically flow from points of higher temperature to points of lower temperature. This occurs without exchanging the actual fluid or gas, just the heat they carry.

Heat exchangers are often used as part of heating (such as indirect water tanks) cooling (such HVAC) or heat recovery systems.

Contents |

[edit] Heat exchange devices

Heat exchange devices can be used in a number of different processes, many of which are used in buildings. Different designs of heat exchange devices can exchange heat between combinations of gases, liquids and solids. Although many are similar systems, they will vary depending on the materials entering and leaving, as well as efficiency. For example a flat plate exchanger will vary in design if it is an air-to-air flat plate exchanger, a liquid-to-liquid flat plate exchanger or a liquid-to-air flat plate exchanger.

These exchange devices may be necessary to avoid contamination of the element being heated, for example in the case of indirect water tanks, radiators or solar thermal units, where a heating fluid retains the heat and transfers this to the water or air via a heat exchange coil in the tank or as with a metal radiator. Not all heat exchangers involve heat recovery but some do.

Below is a list of the types of systems that employ heat exchangers, some for indirect heating, some for heat recovery, and some with a combination of both.

- Air conditioning systems.

- Radiators.

- Indirect hot water tanks.

- Refrigeration.

- Heat pumps.

- Nuclear and power plants.

- Machinery and engines.

- Specialist energy-saving devices such as energy-efficient showers.

[edit] Heat recovery

Heat recovery for buildings refers to the process of capturing and reusing waste heat from different sources, generated from household, industrial or commercial processes. This process is likely to involve heat exchangers.

There are several types of heat recovery which include;

- Air-to-air heat recovery such as ventilation air and exhaust air as in MVHR systems.

- Water-to-water heat recovery such as hot water and cold water, commonly used in manufacturing plants.

- Refrigerant-to-air heat recovery such as in HVAC plant to improve energy efficiency.

- Steam-to-steam heat recovery such as high/ low-pressure steam in power plants and industrial processes.

- Exhaust gas heat recovery from engines, used to generate electricity or preheat air or fuel.

- Phase change materials absorbing from waste heat and releasing on phase change.

- Solids or regenerative, acting as a battery, releasing when needed.

[edit] Forms of heat exchange

There are essentially two main ways heat exchangers work to recouperate heat, which are similar in nature, these are flow and counterflow exchangers, there is a third, with an adjusted approach, known regenerative heat exchange.

[edit] Recouperative flow heat exchange

Flow, in-line parallel or co-current heat exchangers exchange heat between two substances (gas or liquids) when the two elements are flowing in the same direction. Recouperative heat exchangers normally run at higher temperatures with two flows and shorter exchange periods. They are a more direct form of heat exchange and normally more efficient. The materials used are normally metal or plastic.

[edit] Recouperative counterflow heat exchange

Counterflow heat exchangers work by exchanging heat between two elements flowing in different directions. Recouperative heat exchangers normally run at higher temperatures with two flows and shorter exchange periods, they are a more direct form of heat exchange and normally more efficient. The materials used are normally metal or plastic.

[edit] Regenerative heat exchange

Regenerative heat exchangers have single intermittent flows that exchange heat via a third medium acting as a heat battery, so increase in efficiency with the time allowed for the temperature exchange to occur and so can run at lower temperatures. In general when compared with recouperative heat exchangers they are less efficient depending on the circumstances of the waste heat being recovered.

[edit] Typical liquid heat exchange designs

[edit] Shell and tube heat exchanger

A shell and tube heat exchanger is the most common type of heat exchanger, consisting of a cylindrical shell with a bundle of tubes inside. One fluid flows through the tubes, while the other flows around them in the shell. Heat is transferred through the tube walls.

[edit] Plate heat exchanger

A plate heat exchanger consists of a series of thin plates, typically made of metal, with channels for the fluids to flow through. The plates are stacked together, with the fluids flowing between them, allowing heat transfer through the plate walls.

[edit] Finned tube heat exchanger

A finned tube heat exchanger has tubes equipped with fins or extended surfaces that increase the heat transfer area. This allows for more efficient heat transfer, making it ideal for high-temperature applications.

[edit] Double pipe heat exchanger

A double pipe heat exchanger is a simple type of heat exchanger consisting of two concentric pipes, with one fluid flowing through the inner pipe and the other flowing through the outer pipe. Heat is transferred through the pipe walls.

[edit] Spiral heat exchanger

A spiral heat exchanger has two fluids flowing through two separate channels which are coiled around a central core. The two fluids flow in opposite directions, allowing for efficient heat transfer.

[edit] Regenerative heat exchanger

A regenerative heat exchanger uses a matrix of material, such as ceramic, to store heat during one phase of the process and then releases it during another phase. This allows for more efficient heat transfer and is often used in high-temperature applications.

[edit] Typical air heat exchange designs

Air-to-air heat recovery systems are used to transfer heat energy between two streams of air. There are several types of air-to-air heat recovery systems, including:

[edit] Plate heat exchanger

Plate heat exchangers use a series of thin metal plates to transfer heat between two air streams. The plates are stacked and closely separated, allowing the heat to transfer between the two streams.

[edit] Heat pipe heat exchanger

Heat pipe heat exchangers use a closed loop system of pipes to transfer heat between two air streams. The heat pipe contains a fluid that evaporates at a low temperature and condenses at a higher temperature. As the fluid evaporates in one air stream, it transfers heat to the other air stream through the pipe, where it condenses and releases the heat.

[edit] Run-around coil system

A run-around coil system consists of two separate air handling units connected by a network of pipes and heat exchangers. Heat is transferred between the two air streams as they pass through separate coils in each air handling unit.

[edit] Rotary wheel heat exchanger

A rotary wheel heat exchanger uses a rotating wheel made of a heat-conductive material to transfer heat between two air streams. As the wheel rotates, one side absorbs heat from one air stream while the other side releases heat to the other air stream.

[edit] Fixed plate heat exchanger

A fixed plate heat exchanger is designed to recover heat from ventilation air. The exchanger is made up of a series of parallel plates that are closely separated. The ventilation air passes over one set of plates while the exhaust air passes over the other set, allowing heat to be transferred between the two air streams.

[edit] Related articles on Designing Buildings

Featured articles and news

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.

Cutting carbon, cost and risk in estate management

Lessons from Cardiff Met’s “Halve the Half” initiative.

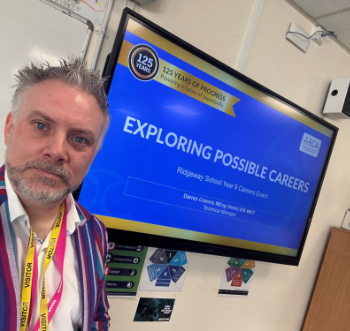

Inspiring the next generation to fulfil an electrified future

Technical Manager at ECA on the importance of engagement between industry and education.

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

Environmental compliance; a checklist for 2026

Legislative changes, policy shifts, phased rollouts, and compliance updates to be aware of.

Comments

[edit] Comments

To make a comment about this article, click 'Add a comment' above. Separate your comments from any existing comments by inserting a horizontal line.